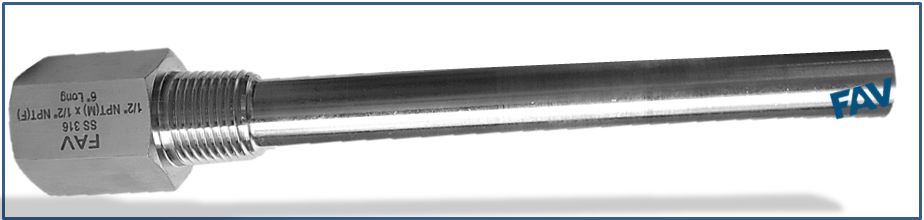

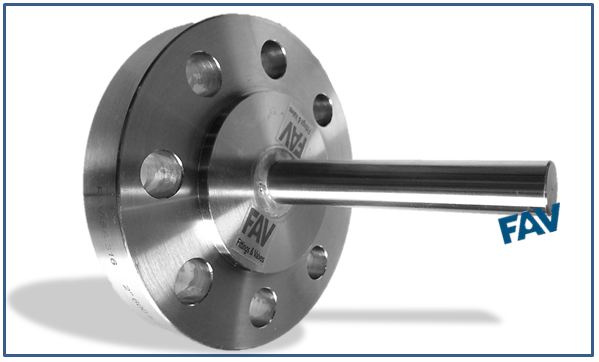

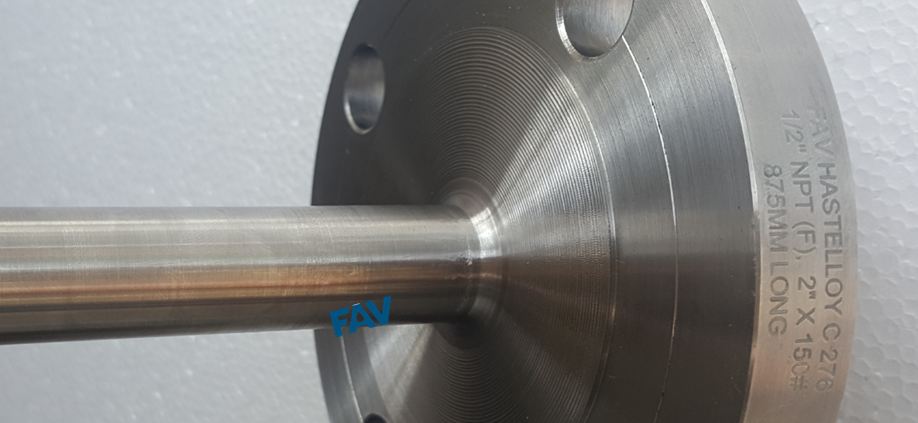

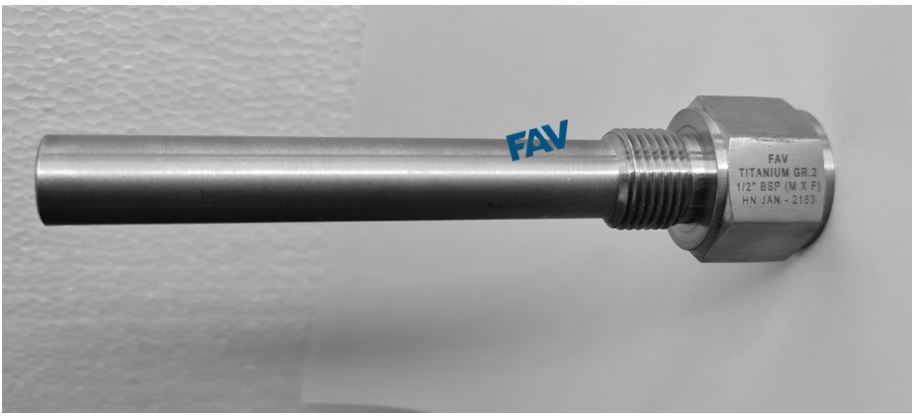

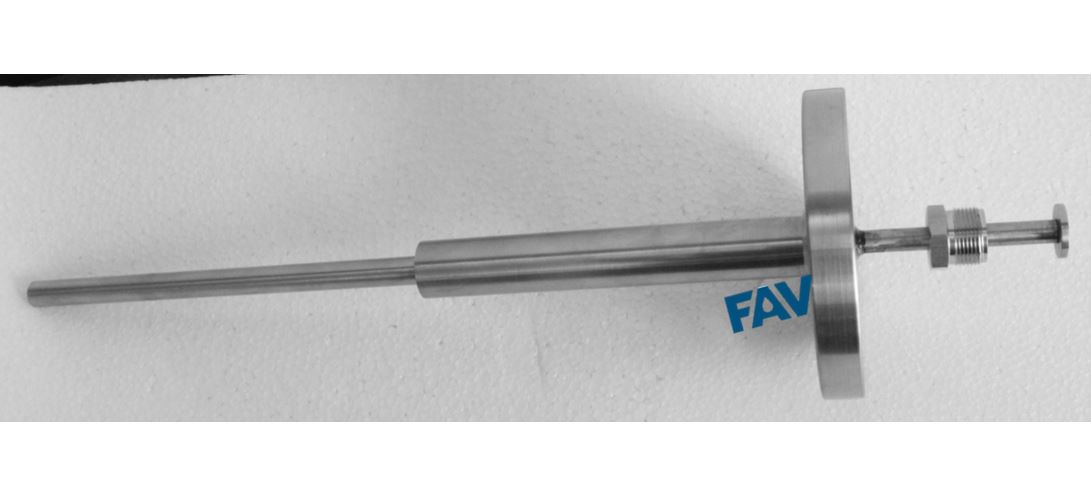

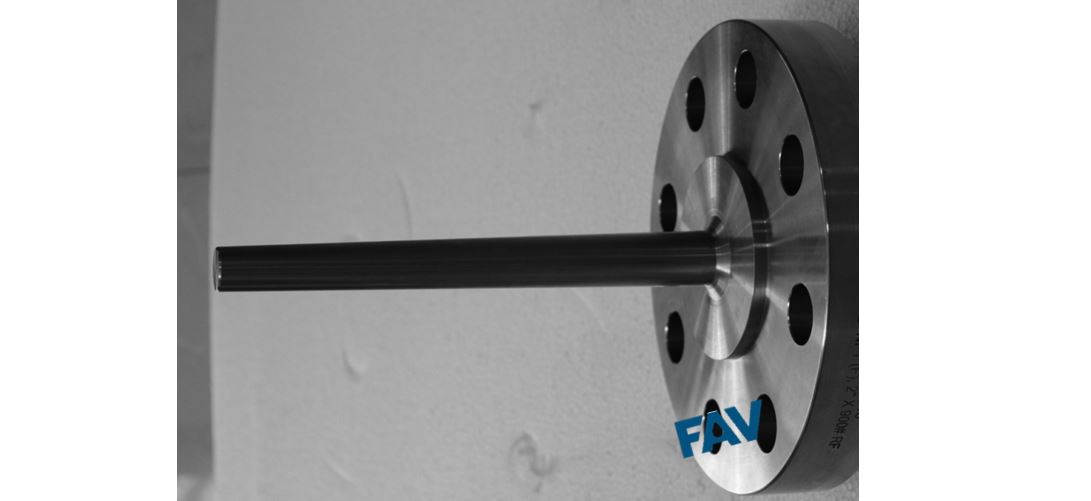

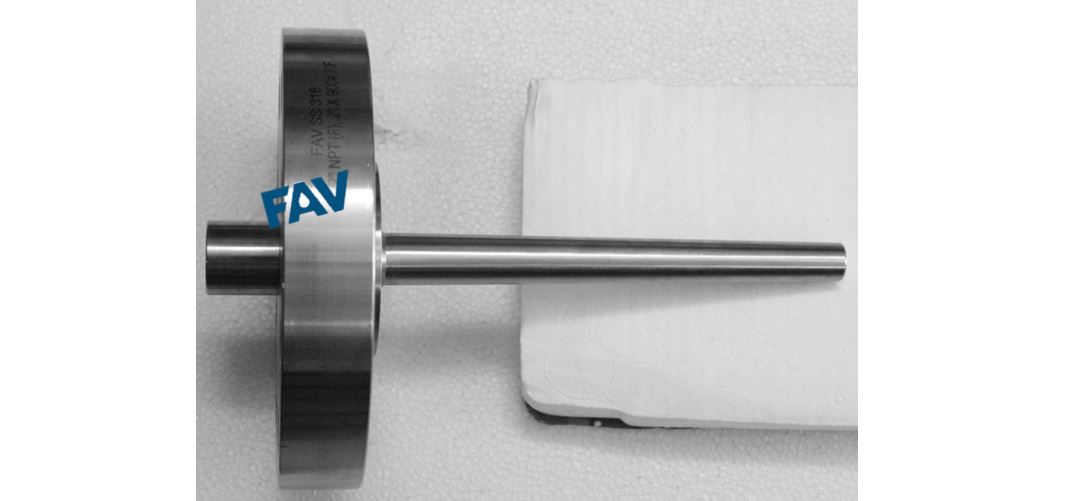

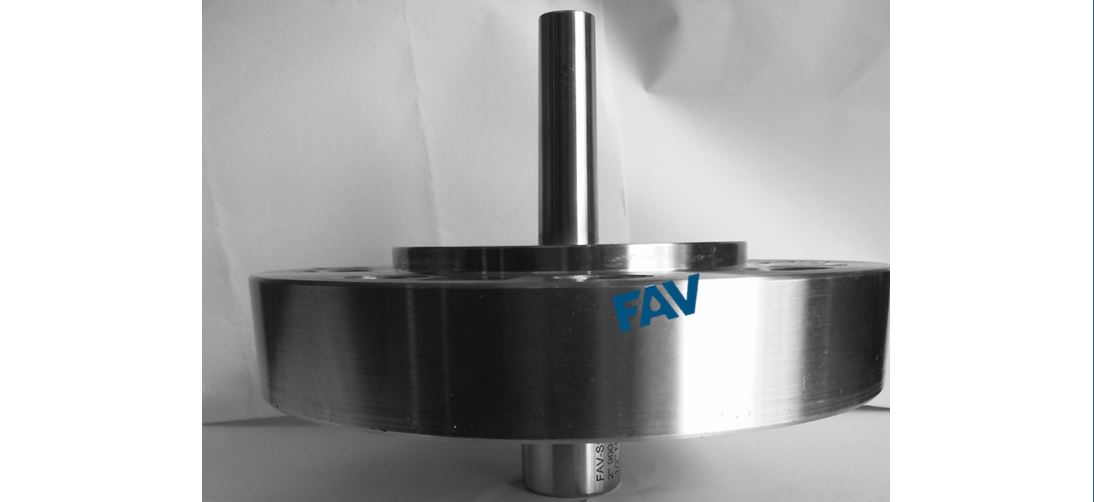

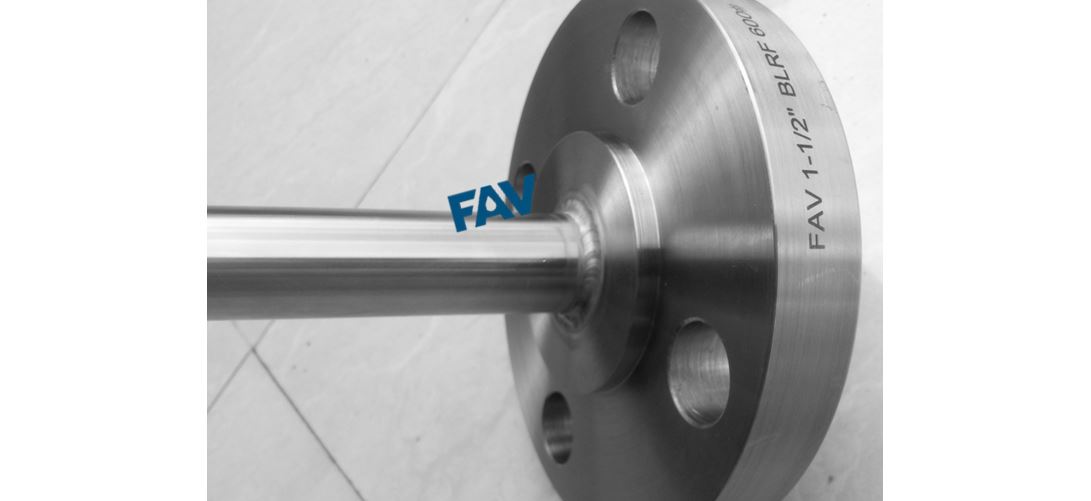

FAV range of Thermowell protects and extends the usage life of a temperature sensor in critical process applications where the sensor is not physically compatible with the environment. Installed directly into the piping systems, thermowells facilitate sensor replacement in high pressure pipelines and eliminate the need to interrupt the process flow or drain the process system for sensor maintenance function. Thermowells are utilized when pressure, high velocity and corrosive process media exist. This serves to isolate and protect the sensing instrument, and permits removal of a sensing instrument without shutting down the process. A perfect solution for protecting the process and extending product service life.

Basic Selection Criteria for Thermowells

Insertion Lengths 2" to 32"

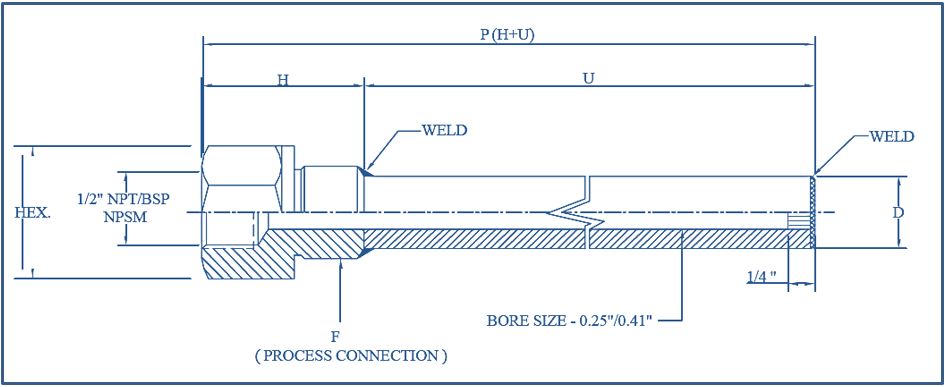

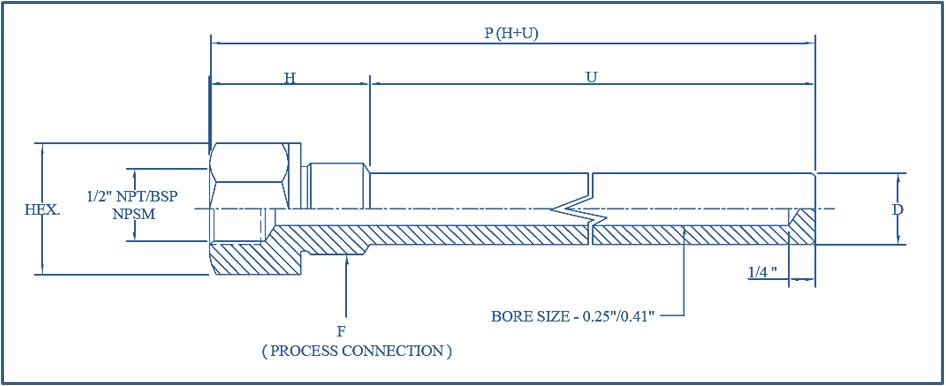

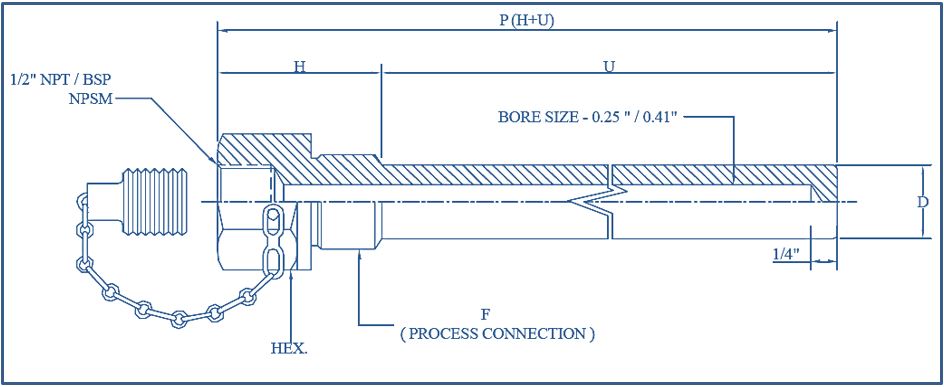

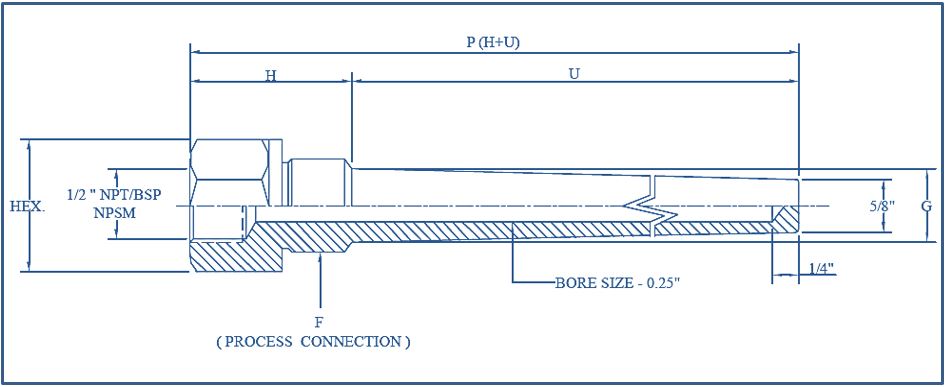

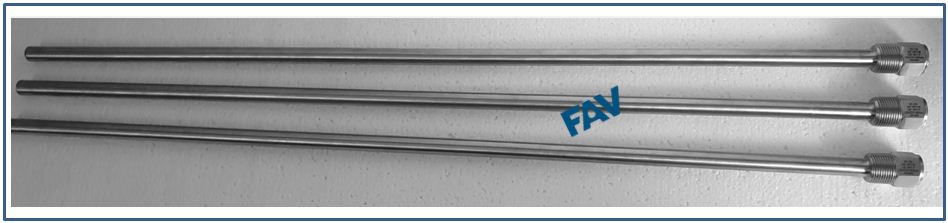

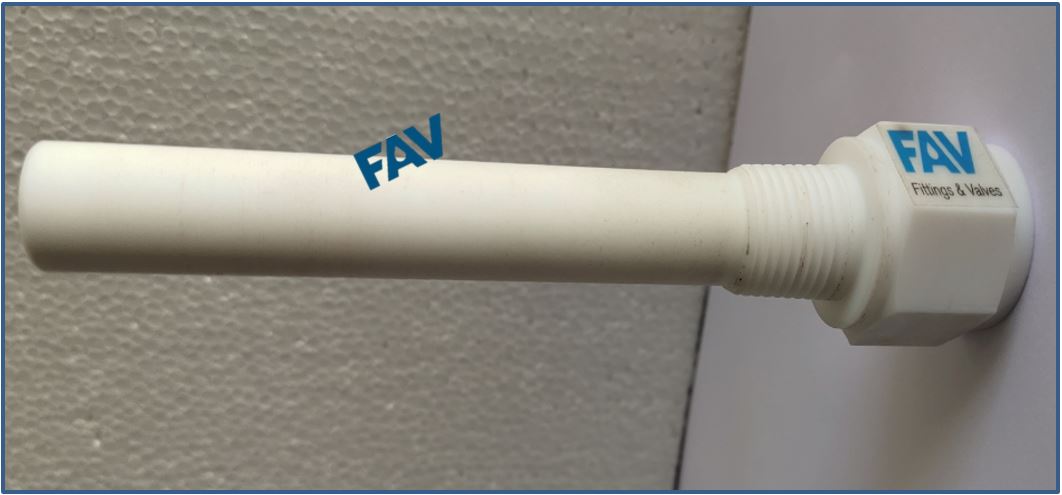

Shank Style Stepped,Tapered, and Straight Shank

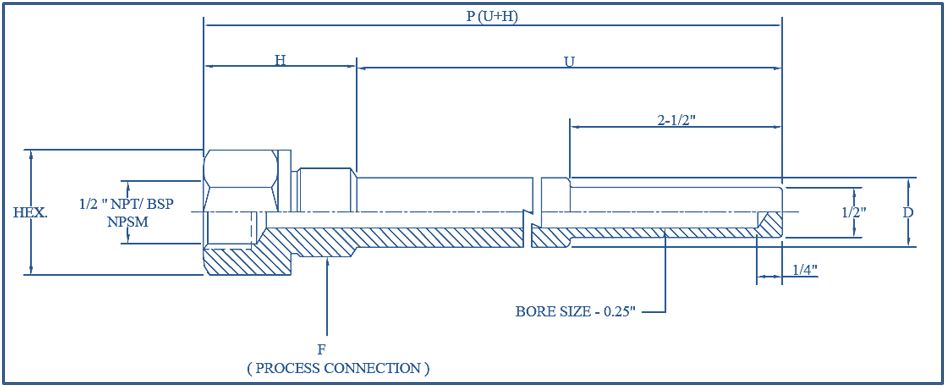

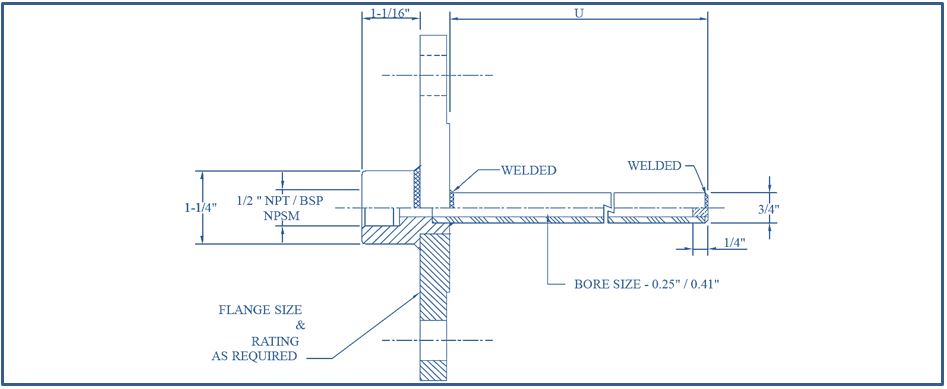

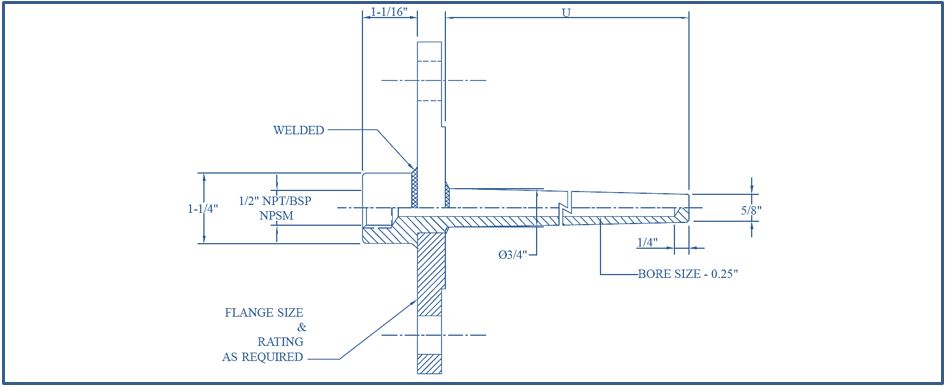

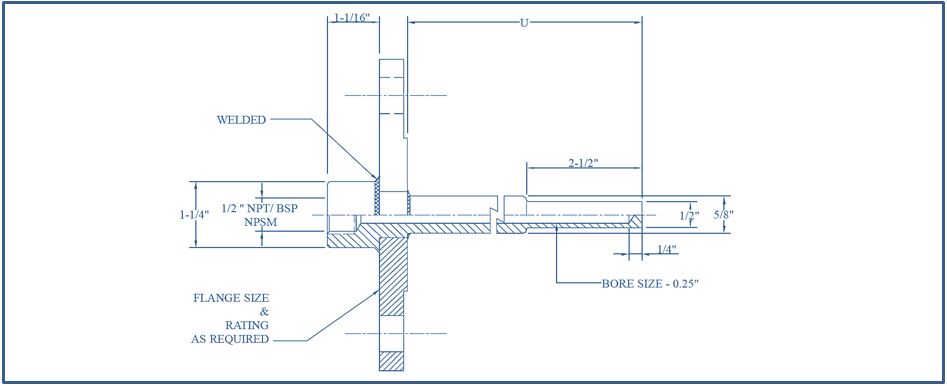

Process connection 1/2" to 2"

Thermowell (Instrument) connection 1/2" to 2"

Bore Size 1/8" to 1/2" (4mm to 12mm)

End Connection NPT,BSP,Weld

Material SS 316 , SS 316L, SS 304 , Brass,Monel 400 and 500 and Hastelloy C 276.Titanium Grade 2