FEATURES

Size Ranges from 1/8" to 2" in fractional series & 6 mm to 38 mm in metric series.

316 Stainless Steel is standard material. Other materials are available upon request.

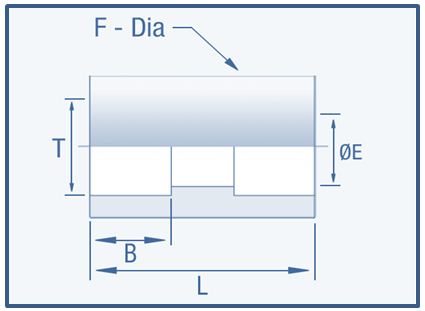

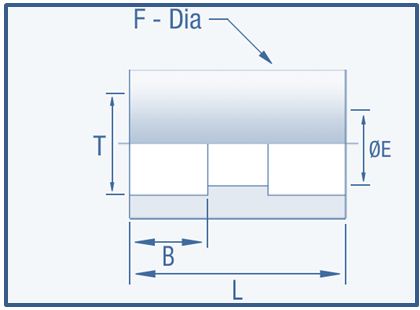

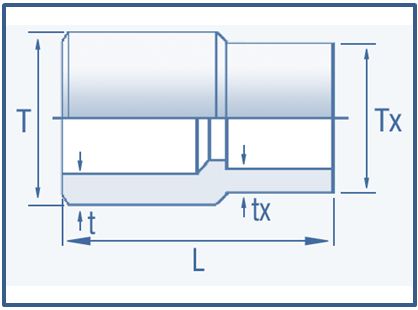

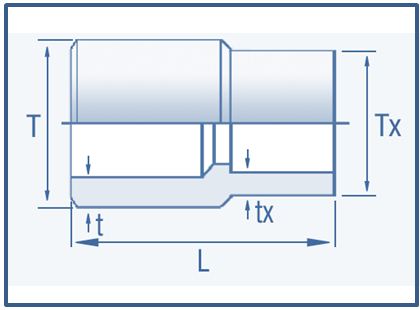

Straight fittings are manufactured from bar stock & Forged fittings are manufactured from forgings.

Quality machining of all ports ensures consistent Welding.

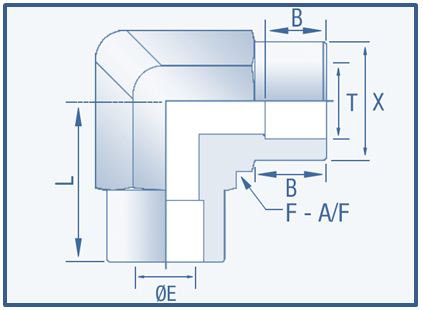

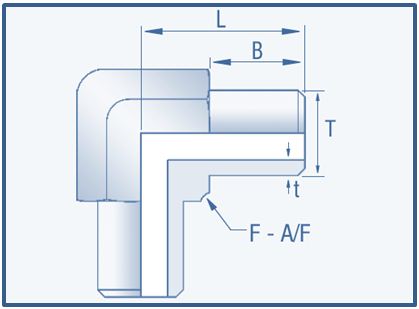

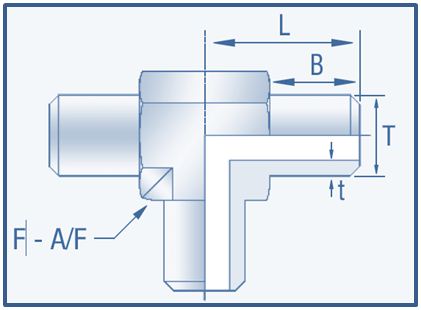

For smooth flow path, elbows are designed with radius junction.

All Fittings are marked with Size, Material and Heat code for easy source tracing.

All threads are capped for protection and properly packaged.

All NPT pipe threads meet the requirements of ASME/ANSI B1.20.1.

Working pressure meets the requirements of ANSI/ASME B31.3 at ambient temperature.

MATERIAL

|

Material |

Bar Stock | Forging | Tubing | |

| Fractional |

Metric |

|||

|

Grade SS 316 |

ASTM A276, ASTM A479, ASME SA276, ASME SA479 |

ASTM A182 ASME SA182 |

ASTM A213 (Seamless). ASTM A249 (Welded). ASTM A269 (Seamless & Welded). |

EN ISO 1127 |

| Grade SS 316L | ASTM A276, ASTM A479, ASME SA276, ASME SA479 |

ASTM A182 ASME SA182 |

ASTM A213 (Seamless). ASTM A249 (Welded). ASTM A269 (Seamless & Welded). |

EN ISO 1127 |

Threads

|

Threads |

Specification |

| NPT Threads |

ASME B1.20.1 |

|

BSPT / ISO Tapered Threads |

ISO 7-1, BS 21, JIS B0203, EN 10226-1, DIN 2999 |

| BSPT / ISO Parallel Threads |

ISO 228-1, BS 2779, JIS B0202 |

INSTALLATION INSTRUCTIONS

To ensure leak proof tight seal, recommends use of pipe thread sealant on all NPT threads. The most effective sealing method is the use of Teflon tape, Tape should be used on male NPT tapered threads. Clean both male and female tapered threads, wrap tape in direction of male tapered, cut off excess tape.

WORKING PRESSURE

Catalogue pressure ratings shown are for temperatures from –20 to 100°F (–28 to 37°C), which are based on an allowable stress value of 20 000 psi (1378 bar) in accordance with ASME B31.3 for 316 stainless steel. To determine working pressures in accordance with ANSI/ASME B31.1, multiply catalogue working pressures shown by 0.94.

Use the allowable working pressure at ambient temperature to multiply the elevated temperature factors to get the working pressure at elevated temperature

WORKING TEMPERATURE

|

Material |

Minimum Working Temperature | Maximum Working Temperature |

|

SS 316 |

-325°F (-198°C) |

1000°F (538°C) |

| SS 316L | -325°F (-198°C) |

850°F (454°C) |

Consult ASME Boiler and Pressure Vessel Code, ASME B31.1, ASME B31.3, or other applicable codes for information on weld setup, technique, and additional considerations for welded systems. The choice of fitting, pipe, and tubing material being welded is critical. Using the same materials will ensure the same coefficients of expansion and will reduce the possibility of poor welds, out-of-roundness, or dimensional changes that are detrimental to a good weld.