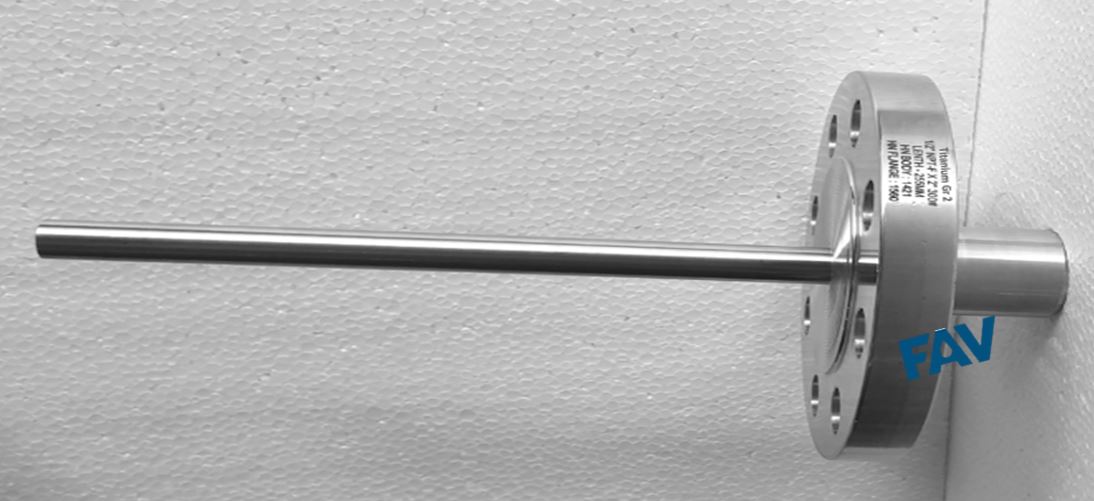

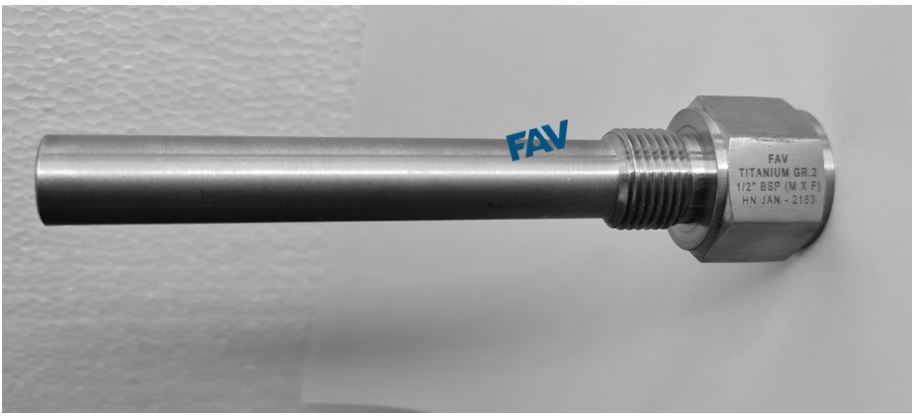

Titanium Grade 2 Thermowells

Fav is the manufacturer Titanium Grade 2 Thermowells, Titanium Flanged Thermowell ,Titanium Straight Thermowell

Properties

Grade 2 titanium machining possesses similar characteristics to austenitic stainless steel. Although titanium is commonly perceived as challenging to machine, Grade 2 can be machined easily by following the recommended protocol—low cutting speeds, heavy feed rates, generous amounts of cutting fluids, sharp tools and rigid setups.

Applications

The high strength, low weight ratio and outstanding corrosion resistance inherent to titanium and its alloys has led to a wide and diversified range of successful applications which demand high levels of reliable performance in surgery and medicine as well as in aerospace, automotive, chemical plant, power generation, oil and gas extraction, sports, and other major industries.

In the majority of these and other engineering applications titanium has replaced heavier, less serviceable or less cost-effective materials. Designing with titanium taking all factors into account has resulted in reliable, economic and more durable systems and components, which in many situations have substantially exceeded performance and service life expectations.

Advantages

Grade 2 titanium is called the “workhorse” of the commercially pure titanium industry, thanks to its varied usability and wide availability. It shares many of the same qualities as Grade 1 titanium, but it is slightly stronger. Both are equally corrosion resistant.

This grade possesses good weldability, strength, ductility and formability. This makes Titanium Grade 2 Thermowells the prime choice for many fields of applications..

Advantages of Titanium Grade 2 Thermowells

- Titanium Thermowells do not twist during installation.

- Low torque Operation

- Positive leak free seal assembly and reassembly

- Variety of end connections and patterns as per Customer Requests